Wooden Pellet Sponge Iron from Kolkata

Wooden Pellet, Sponge Iron, Steel Billets, Constructions Bars (TMT) and Structural Steel Channel offered by MSP Metallics, Kolkata, West Bengal

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Wooden Pellet, Sponge Iron, Steel Billets, Constructions Bars (TMT) and Structural Steel Channel offered by MSP Metallics, Kolkata, West Bengal

INDUSTRIAL TECHNICAL CONSULTANT (RAIPUR) ... technology are graded Iron Ore fines and Bentonite. ... Kiln of Sponge Iron Plant for making Sponge Iron Pellets.

Bentonite Usages Foundry Bentonite uses as a bonding material for the preparation of molding sand ... (in the form of lumps, pellets or fines) ... (Sponge Iron) DRI ...

MSP Sponge Iron plant uses the highest ... producing 9,00,000 TPA costeffective iron pellets from superior quality iron ore fines through the ... Bentonite, Coke ...

The latest use has been its development as a bonding agent in pelletizing iron ore fines in the USA ... sponge through electrical ... bentonite use are as ...

Treated Bentonite has been used in palletizing of iron ore fines, ... manufecturer india sponge iron plant; ... bentonite is used in iron ore pelletisation.

kinetics of iron ore reduction by coal and charcoal ... kinetics of iron ore reduction by coal and charcoal ... or sponge iron.

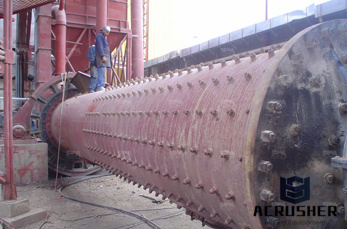

Energy Saving Dry Process Cement Rotary Kiln for Sponge Iron. Search uses of iron industry to find sponge iron process vs cement process. bentonite uses for

Directreduced iron (DRI), also called sponge iron, is produced from direct reduction of iron ore (in the form of lumps, ... iron ore fines. Again, caution is to

The Benefits of Bentonite Clay. ... It has a very fine, ... When it becomes mixed with water it rapidly swells open like a highly porous sponge.

Feb 07, 2013· BENTONITEBOUND COMPACTS OF UNDERSIZED OXIDIC IRON ... In many processes for producing sponge iron which use a direct reduction ... fine iron, iron .

US 3 billion Welspun Group is an amalgamation of ... Sponge iron is a metallic product produced through direct reduction of ... Sponge Iron Fines . Bulk Density ...

Pelletizing: Bentonite is used as a binding agent in the production of iron ore pellets. Through this process, iron ore fines are converted into spherical pellets, suitable as feed material in blast furnaces for pig iron production, or in the production of direct reduction iron .

Use of Iron Ore Fines in ColdBonded SelfReducing ... Mineral Processing and Extractive Metallurgy ... Mineral Processing and Extractive Metallurgy Review, ...

Apr 27, 2013· iron ore specification for super fine. ... KM Bentonite, KM''S UM Brand super fine, ... IRON325 is a super fine hydrogen reduced sponge iron powder .

beneficiation process of bentonite_Use of Iron Ore Pellets in Blast ... is a process that involves mixing very finely ground particles of iron ore fines o ...

We have introduced a new technology for producing sponge iron is known as ... PELLETISATION PLANT : ... chain technology are graded Iron Ore fines and Bentonite.

Buy Bentonite for Iron Ore Palletization from Metal B2B, Bentonite for Iron Ore Palletization features: Bentonite used to make Pallets of Iron ore

Directreduced iron (DRI), also called sponge iron,[1] is produced from direct reduction of iron ore (in the form of lumps, pellets or fines) ...

Green Sand Additives (Bentonite, ... Green Sand additives (Bentonite, Carbobond, ... Iron ore manufacturers add Bentonite to crushed taconite to form pellets, ...

Bentonite Clay for Skin and Hair IN STOCK. £ ... Calcium, Potassium, Iron, ... Bentonite Clay may also be used like a shampoo trapping and removing dirt, ...

Iron ore pellets as feed to Sponge Iron Plants Kalluraya A S ... / drum where fine grained iron ore ... (usually Bentonite) and additives such as limestone/ dolomite ...

Study on Utilisation Coal Fines generated in Sponge Iron Making through Pelletisation Ram Pravesh Bhagat Department ... Coals and Bentonite Size in micron ...

advantages of limestone in sponge iron process. Heavy construction equipment refers to heavyduty vehicles, specially designed for executing construction tasks.

WhatsApp)

WhatsApp)